Brief Introduction

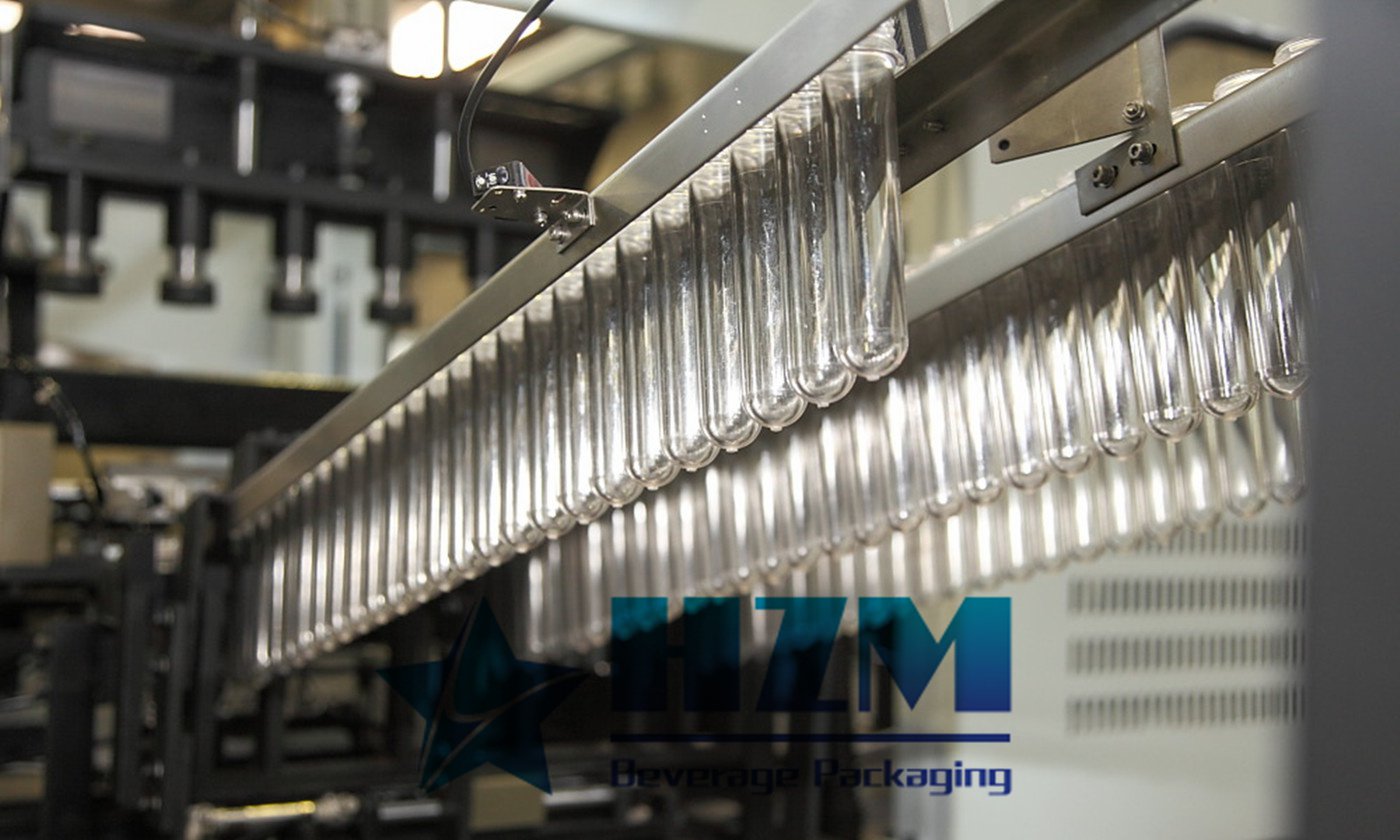

Full electrical servo type blow molding machine is mainly used for all kinds of plastic bottle pre-form stretching. Far-infrared lamps are heat source, through servo motor driving chain to make pre-forms turning around for heating. Then performs go into mold and blowing into bottle by high pressure air.

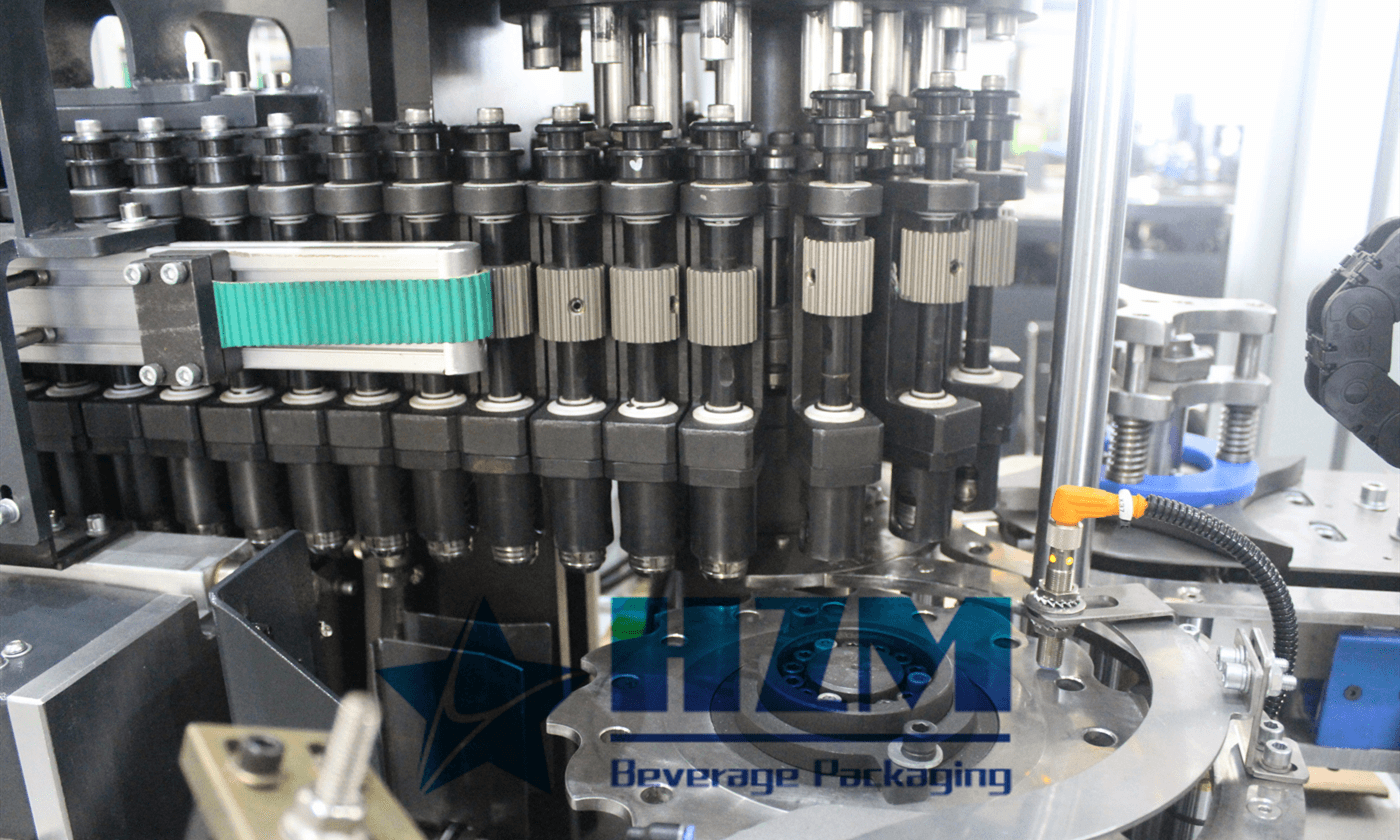

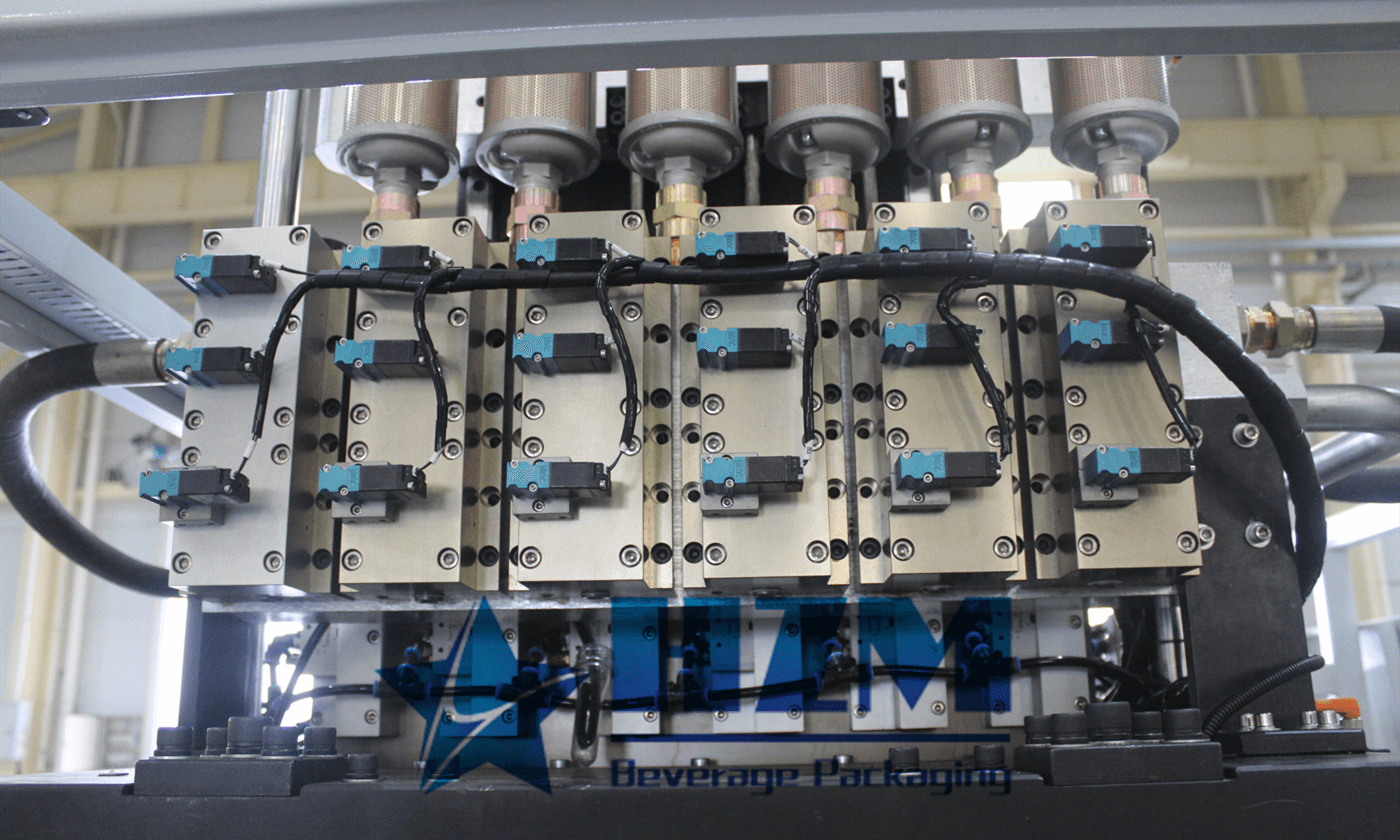

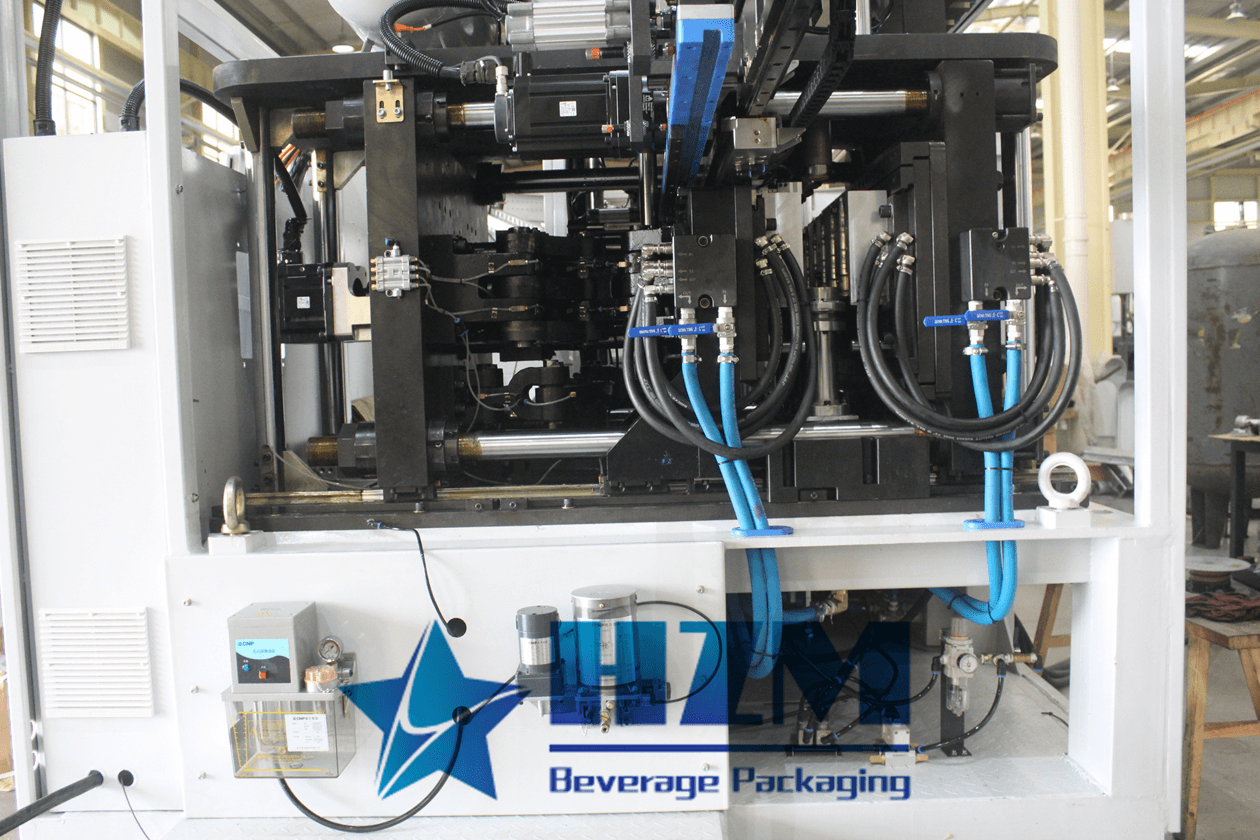

Blowing machines parts should be smoothly running, action coordinated, precise mould closing, sensitive reaction and clear and accurate instructions. And these parts can cooperate with mould into qualified products. Adopting touch screen operation and running state is clear.

Main electrical components (touch screen, etc) adopts famous-brand products, power cylinder mainly adopts FESTO, SMC, Parker etc assuring its stability and durable.