Brief Introduction

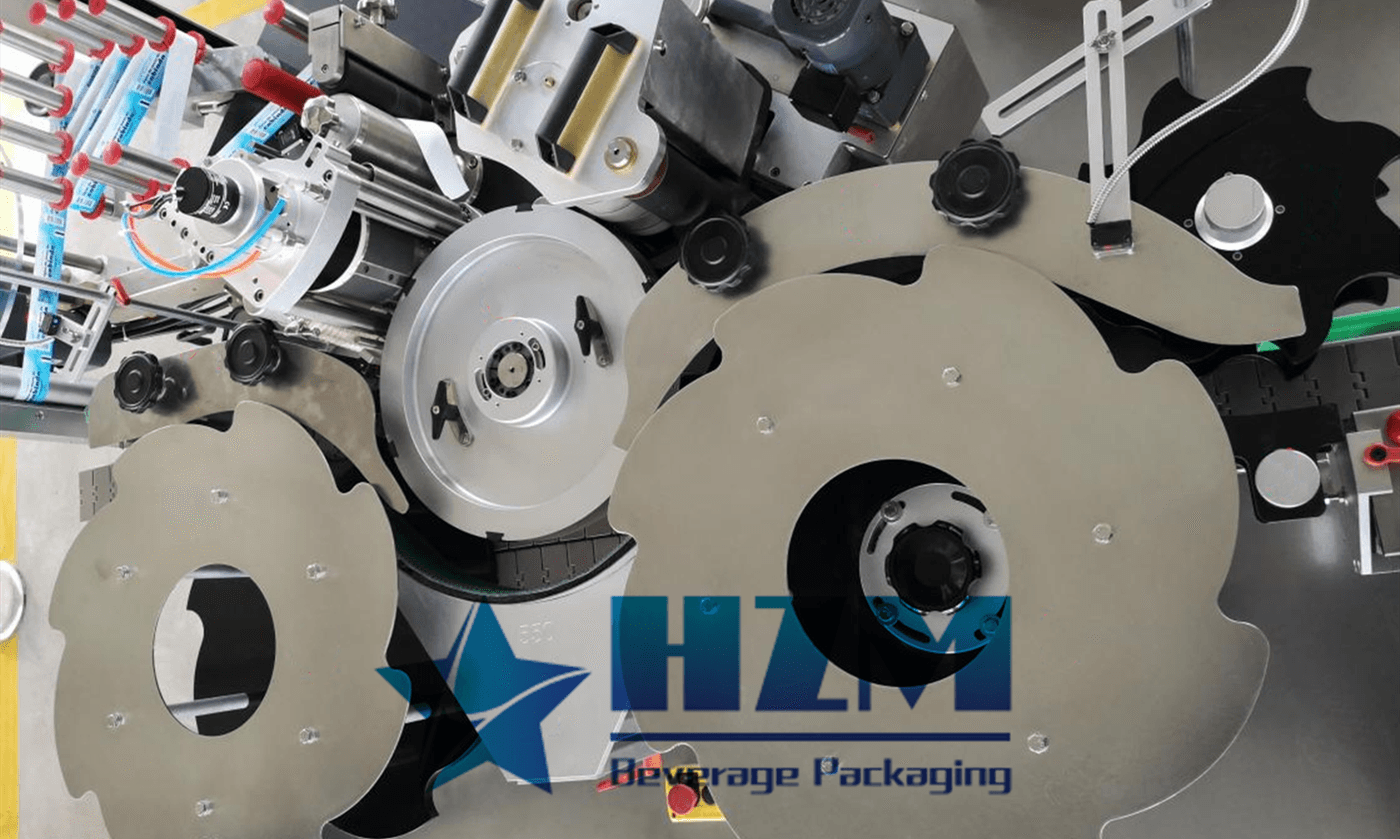

Linear OPP hot gule adhesive labeling machine is the advanced continous operation of the labeling machine. The mainly used for container labeling cylindrical shape of detergents, beverages, mineral water, food etc. The material of label are using environmentally material of OPP films. It can be automatically oxidative decomposition and reduce production costs by more than 30%. Labeling machine is control by PLC HIM, all electrical sensors are using imported advanced configuration. This labeling machine with high speed, high accuracy, stable performance, easy to operate and look elegant appearance.