Brief Introduction

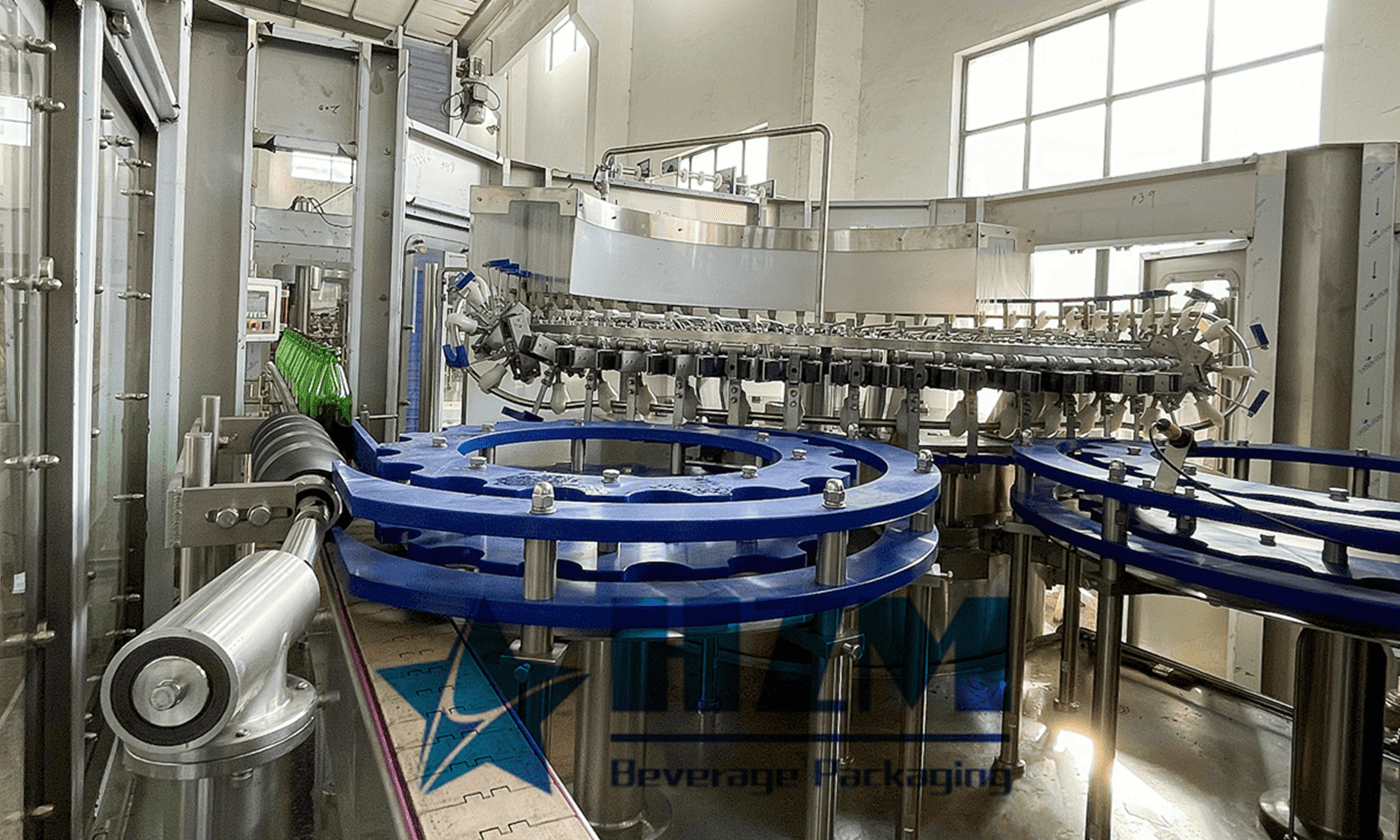

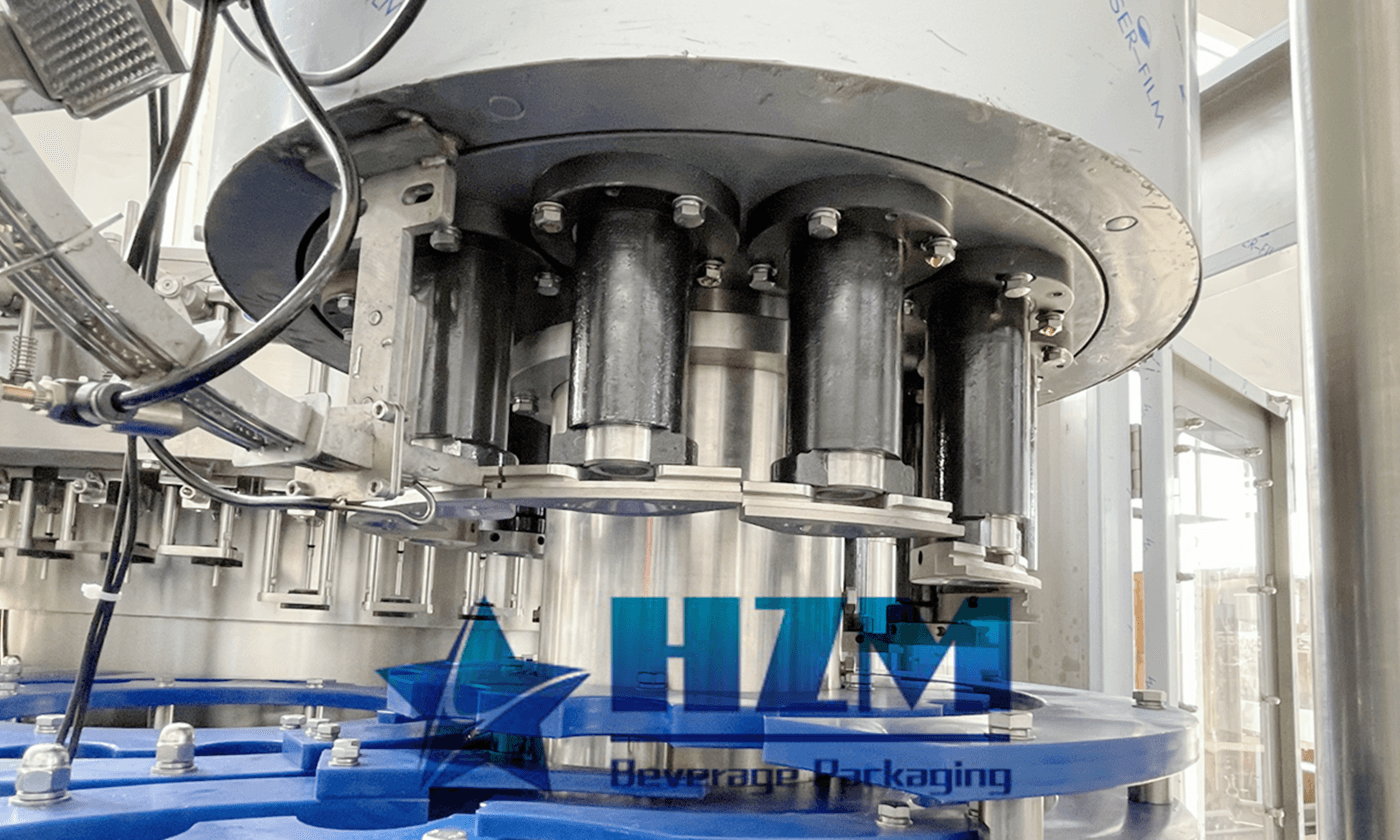

Glass bottle juice beverage filling machine has a unique design combining the three parts of bottle washing, filling and capping in one machine to decrease main power, save space and avoid the air pollution among the three parts. It is automatic in total process and suitable for all kinds of fruit juice, tea drinks, energy drinks etc which is used for filling pet bottle. Glass bottle juice filling machine can use hot filling and mid-temperature filling technology according to customer filling process requirements. It also can be used for mineral water, pure water and many other no gas containing drinks.